There are a number of reasons to turn to Carlyle for process chiller applications. Let’s start with 200,000

That’s the approximate number of Carlyle compressors currently installed in chiller applications around the world today. That’s because, whether you’re talking manufacturing or building air conditioning, customers know they can count on Carlyle to drive the cooling solution they need.

Buildings today account for 40 percent of all energy usage worldwide. The HVAC systems that control their environments account for 40 percent of energy usage inside those buildings. Cooling for manufacturing also requires a great deal of energy. What does it mean for compressors? Simple. Efficiency is everything – and Carlyle delivers.

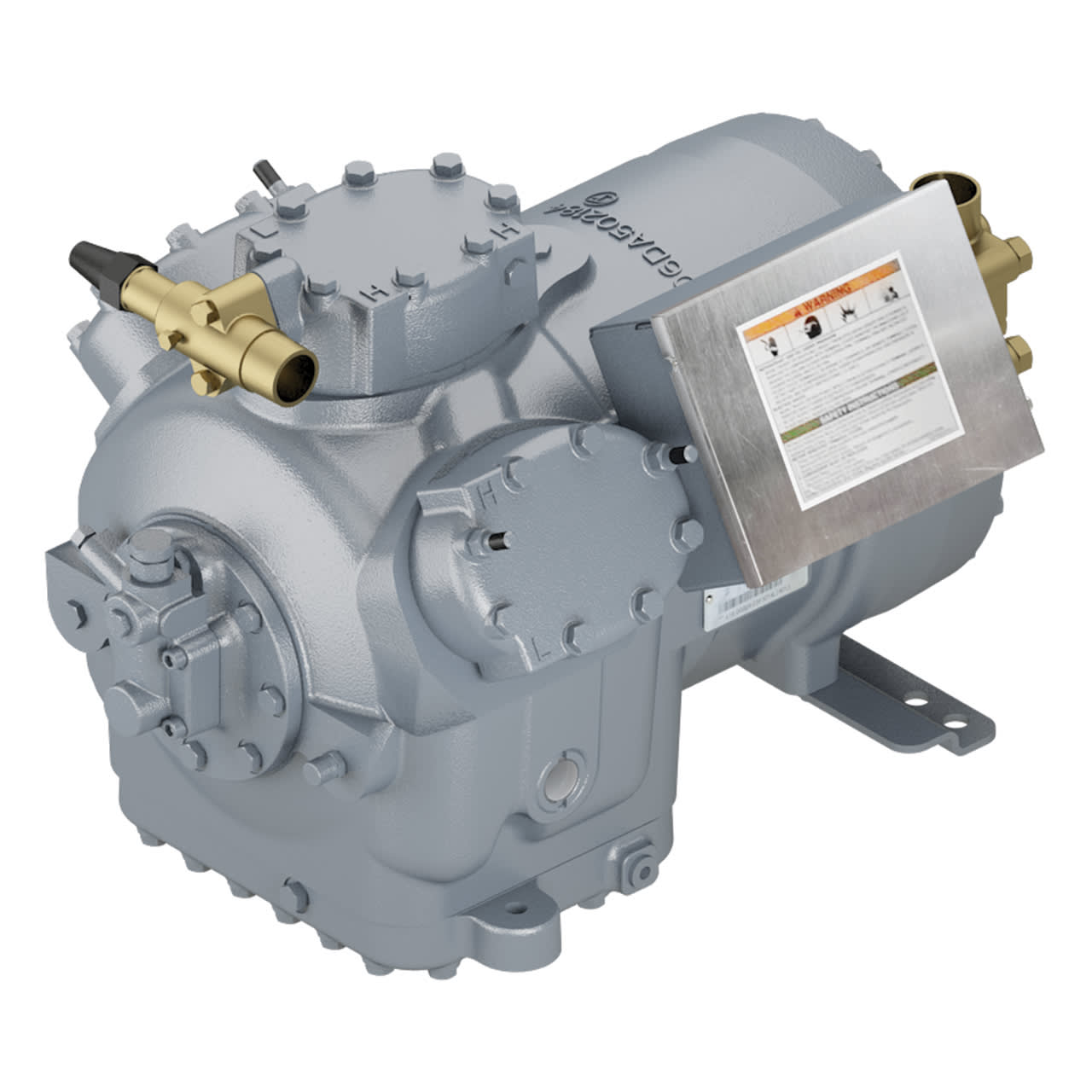

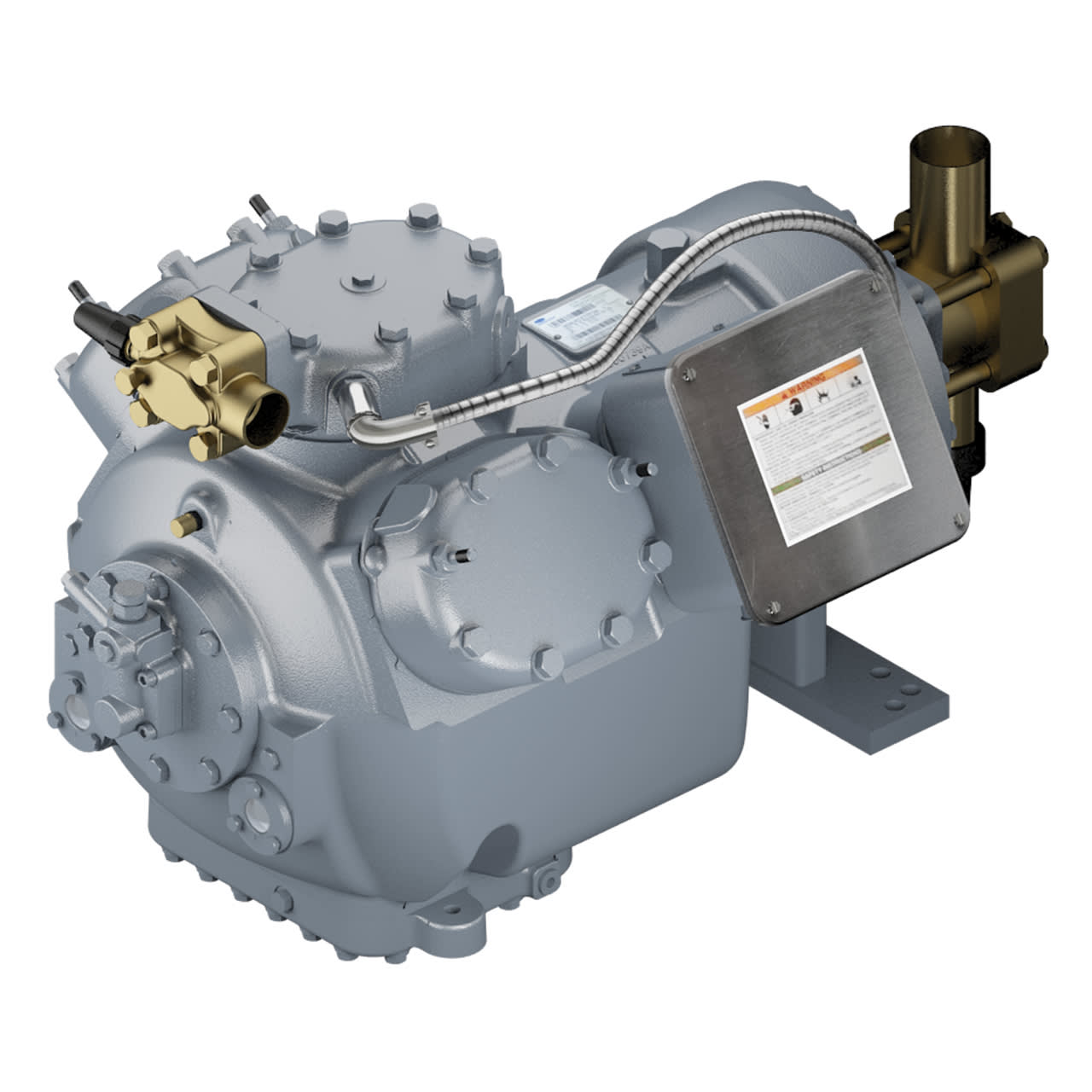

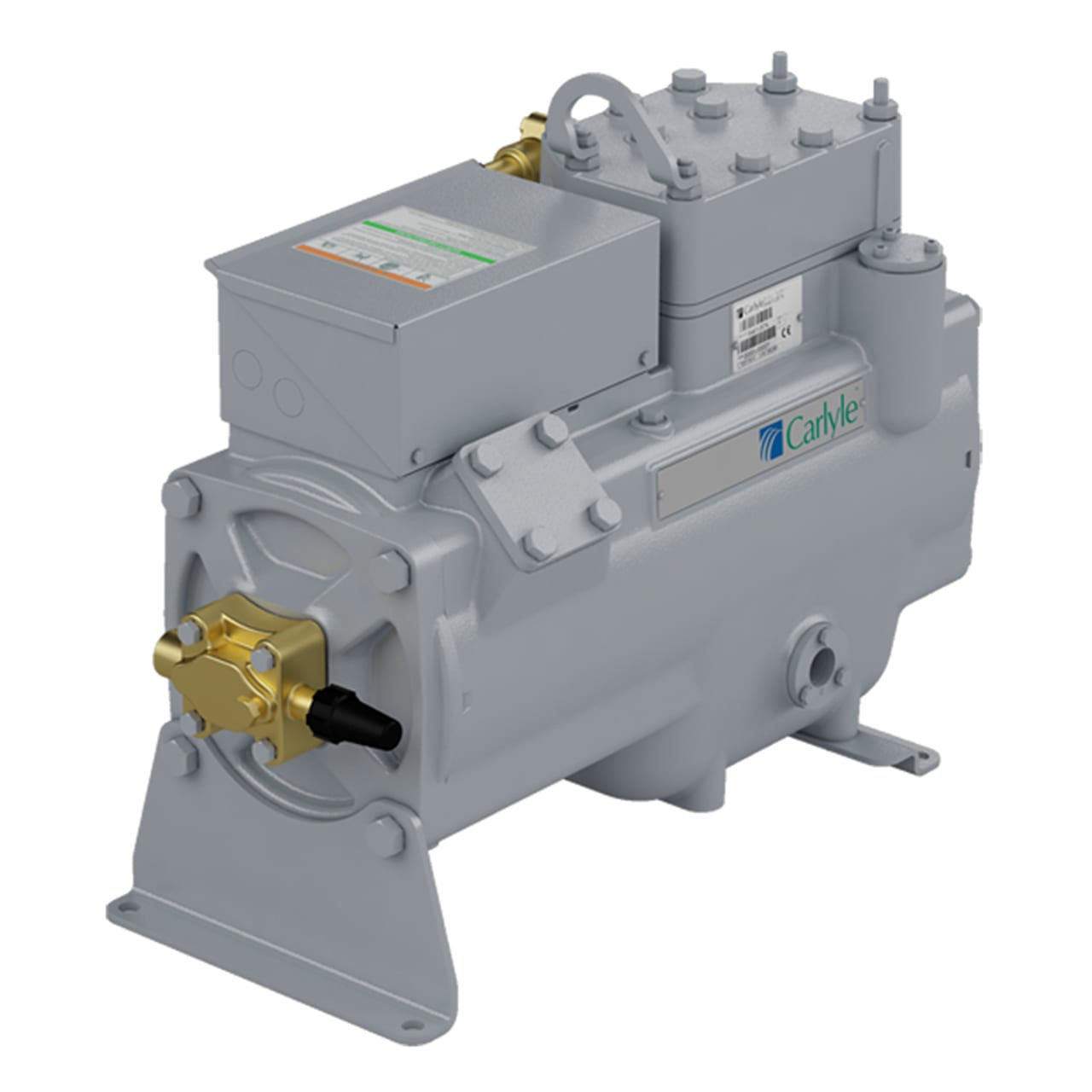

While our 06D, 06E and new 06M with R-410A refrigerant, are highly effective choices for smaller capacity applications, our new Paragon screw compressor delivers impressive advantages for larger capacity needs.

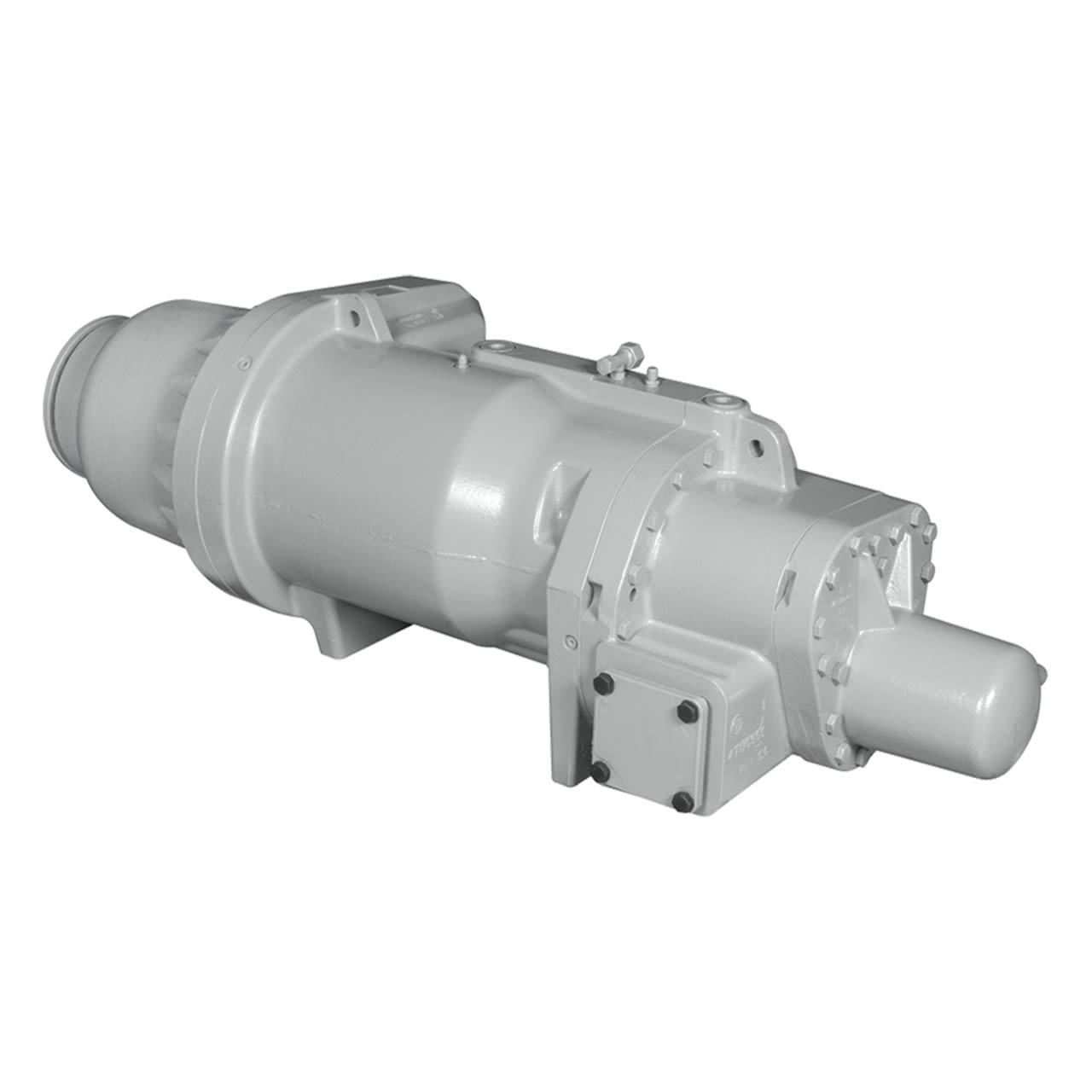

The product of extensive research and development, and decades of Carlyle expertise, Paragon features full-load capacities ranging from 35 to 300 tons, with best full- and part-load efficiencies, and perfect load matching by using continuous unloading down to 25 percent. This level of performance can be provided because Paragon is specifically optimized for low- and medium-temp refrigeration as well as high-temp applications. Plus, units have pre-engineered oil management for easy application and 100 percent factory-run tested for superior quality and reliability.

It’s easy to see that Paragon – along with Carlyle’s full line of offerings for process cooling applications – offers no shortage of technical benefits. They can all be distilled down to one important idea: the performance of a cooling system hinges on that of its compressor, and Carlyle compressors deliver high performance with low operating costs.