Preserve perishables while protecting the bottom line with Carlyle compressors for commercial refrigeration rack applications.

Owners and operators of stores today are tasked with maintaining a high level of freshness and quality for a wide range of food products, all while keeping operating costs as low as possible. It’s a complex, twofold challenge – but there’s one company that is uniquely equipped to solve it.

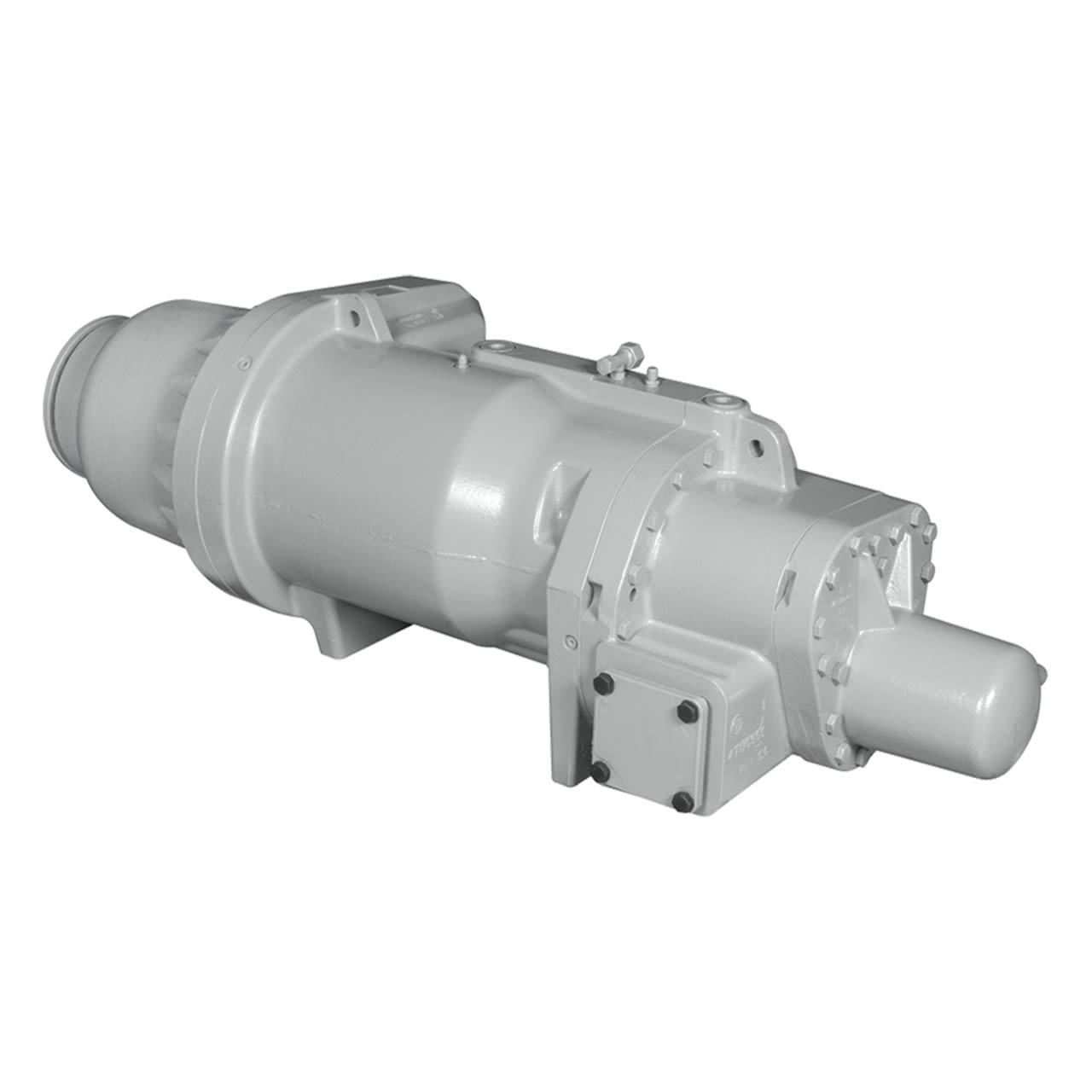

Carlyle has long been a trusted name in the supermarket industry. Our compressors power advanced cooling and refrigeration solutions that help maintain the integrity of perishable foods by allowing for precise, consistent control of temperatures. And they do so in a way that emphasizes operating efficiency.

Understanding that downtime can translate to lost inventory and lost revenue, Carlyle compressors for commercial rack applications set the highest standards for reliability. In a head-to-head independent study of supermarket refrigeration racks, Carlyle compressors had an average life span of 9.9 years, nearly double that of the leading competitor's compressor of 5.2 years. That reliability can translate to a $15,000 savings per store in critical downtime, repair and replacement costs.

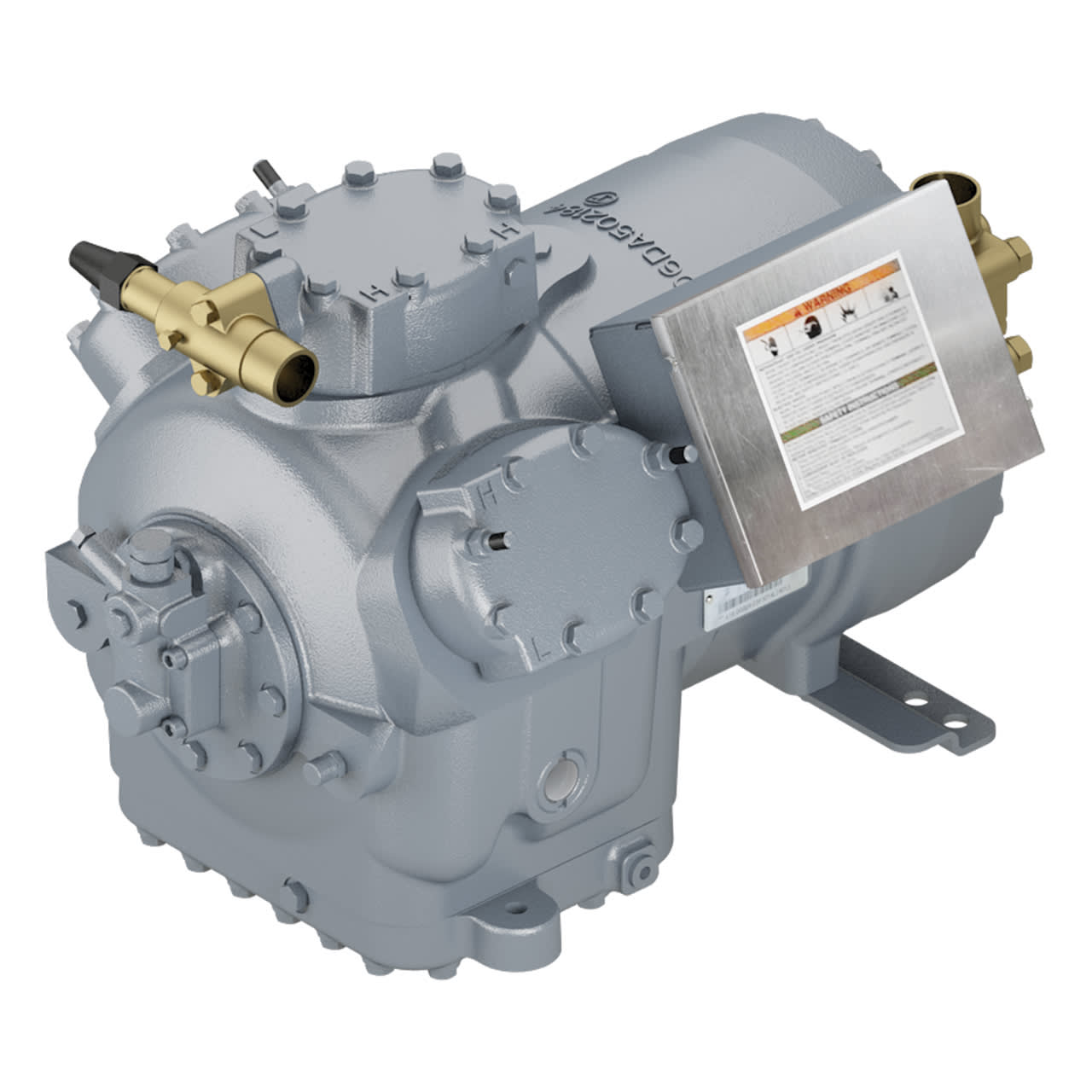

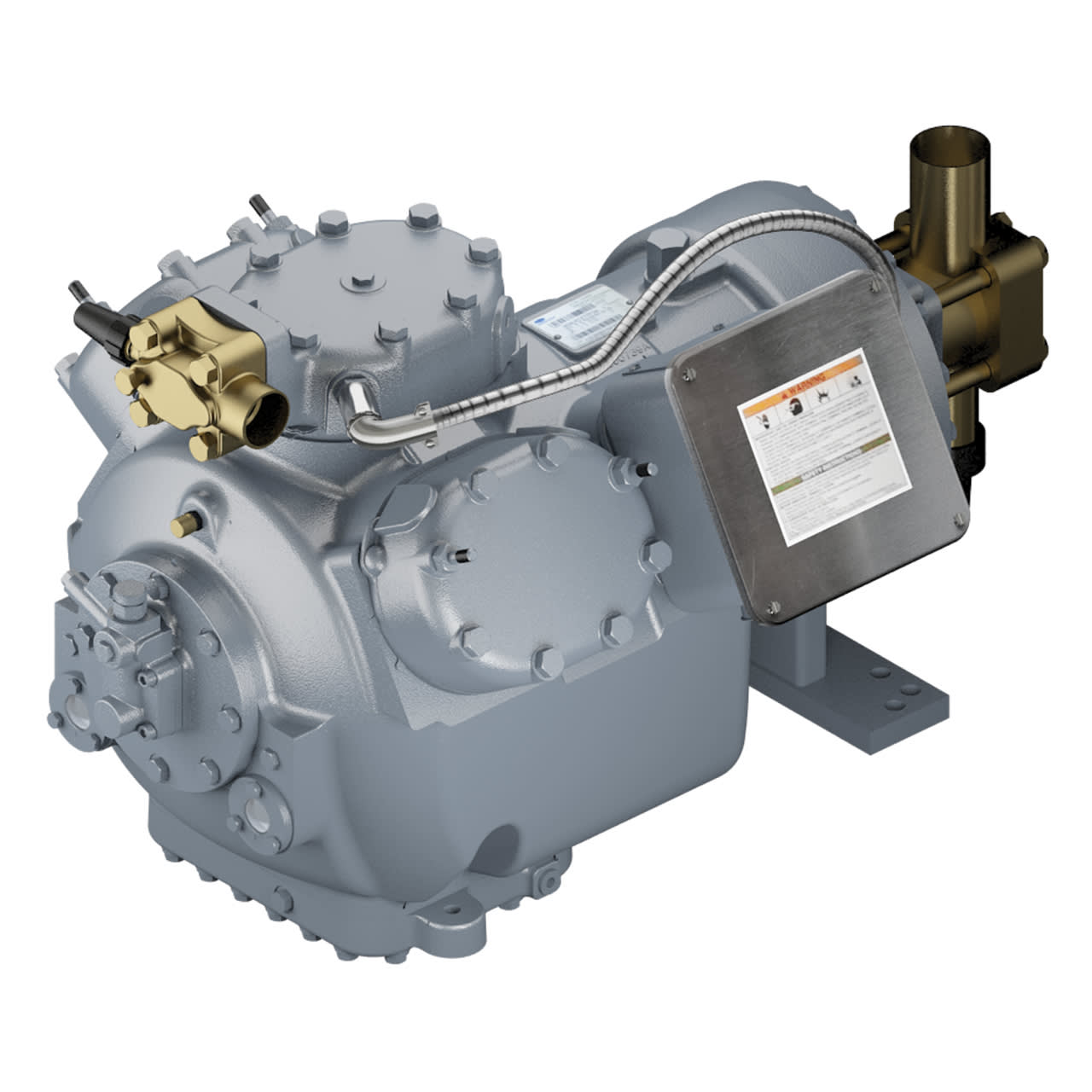

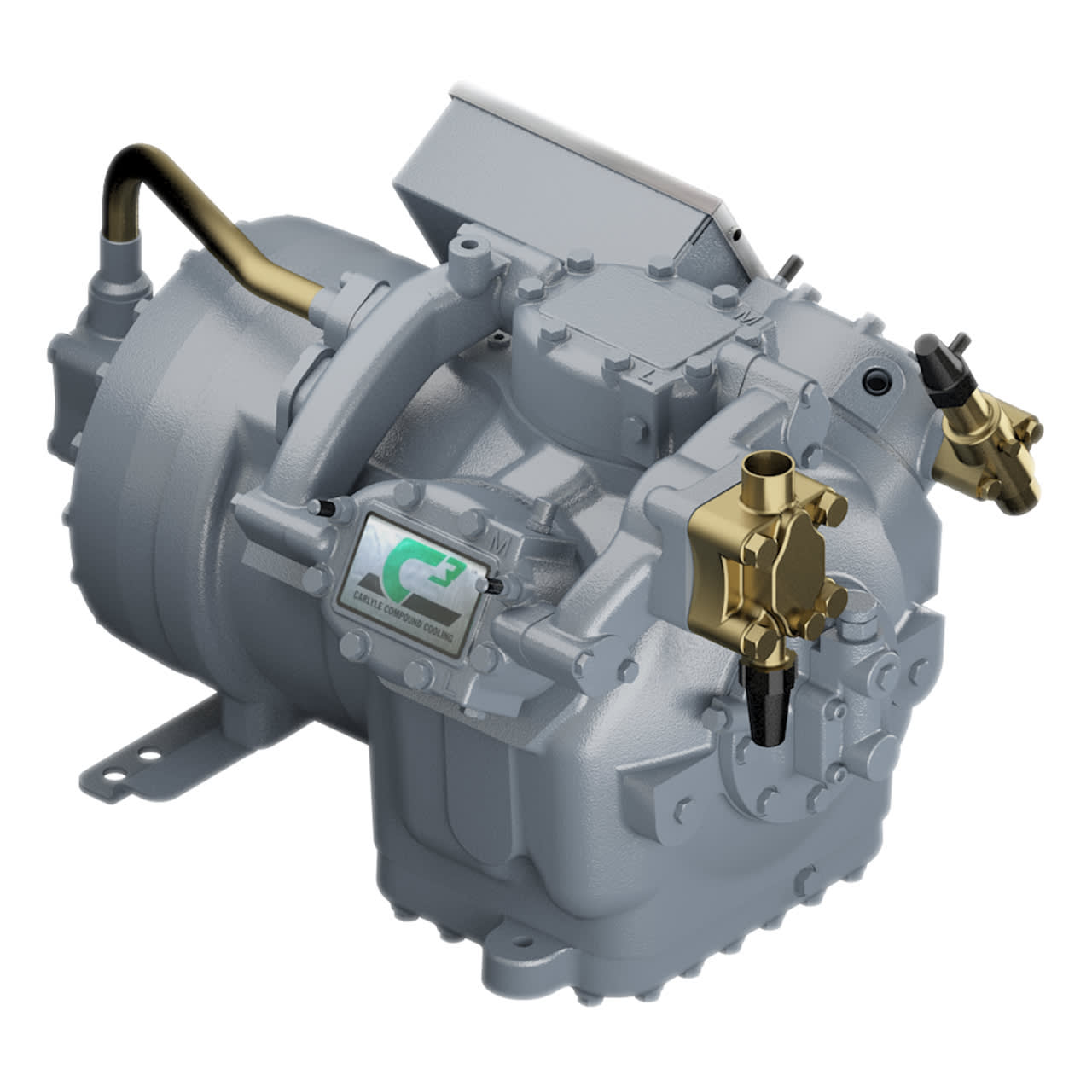

It’s also the level of reliability that has made our 06D and 06E reciprocating compressor one of the industry’s top choices. Throughout the years, customers have relied on Carlyle to deliver high efficiency, low operating costs and, of course, the toughness for which we have become famous. But we didn’t quit while we were ahead. We consistently upgrade and make improvements, introducing innovations like the intelligent, versatile 06M. It’s a classic case of the best continuing to get better.

In fact, the same can be said for our entire range of commercial refrigeration compressor solutions. We’re always working to deliver more products operating at more temperature ranges than any other company in the business.